Case Center

An old customer from Mexico repurchased the cable recycling machine and packed it for delivery.

August 20, 2024In recent years, the cable recycling industry has gradually become an important business in the global environmental protection field, with broad development prospects and rich market returns. Against this background, a local cable recycler in Mexico has demonstrated its long-term business vision and decided to increase investment in cable recycling equipment. This customer purchased a double-shaft shredder from SUNY Group a year ago to process waste plastics. This equipment has excellent performance and helped customers effectively improve the efficiency of plastic recycling. Customers highly praised SUNY Group’s equipment quality and services.

Based on the previous successful cooperation experience, this Mexican customer is well aware of the huge potential of the cable recycling industry, so he decided to further expand his business and invest in more advanced equipment. After detailed market research and technical consultation, the customer finally chose SUNY Group again and purchased a set of cable recycling equipment with an output of 700 kg per hour. This set of equipment includes pretreatment system, crushing system, separation system, etc., which can efficiently process waste cables and realize the separation and recycling of copper, aluminum and plastics.

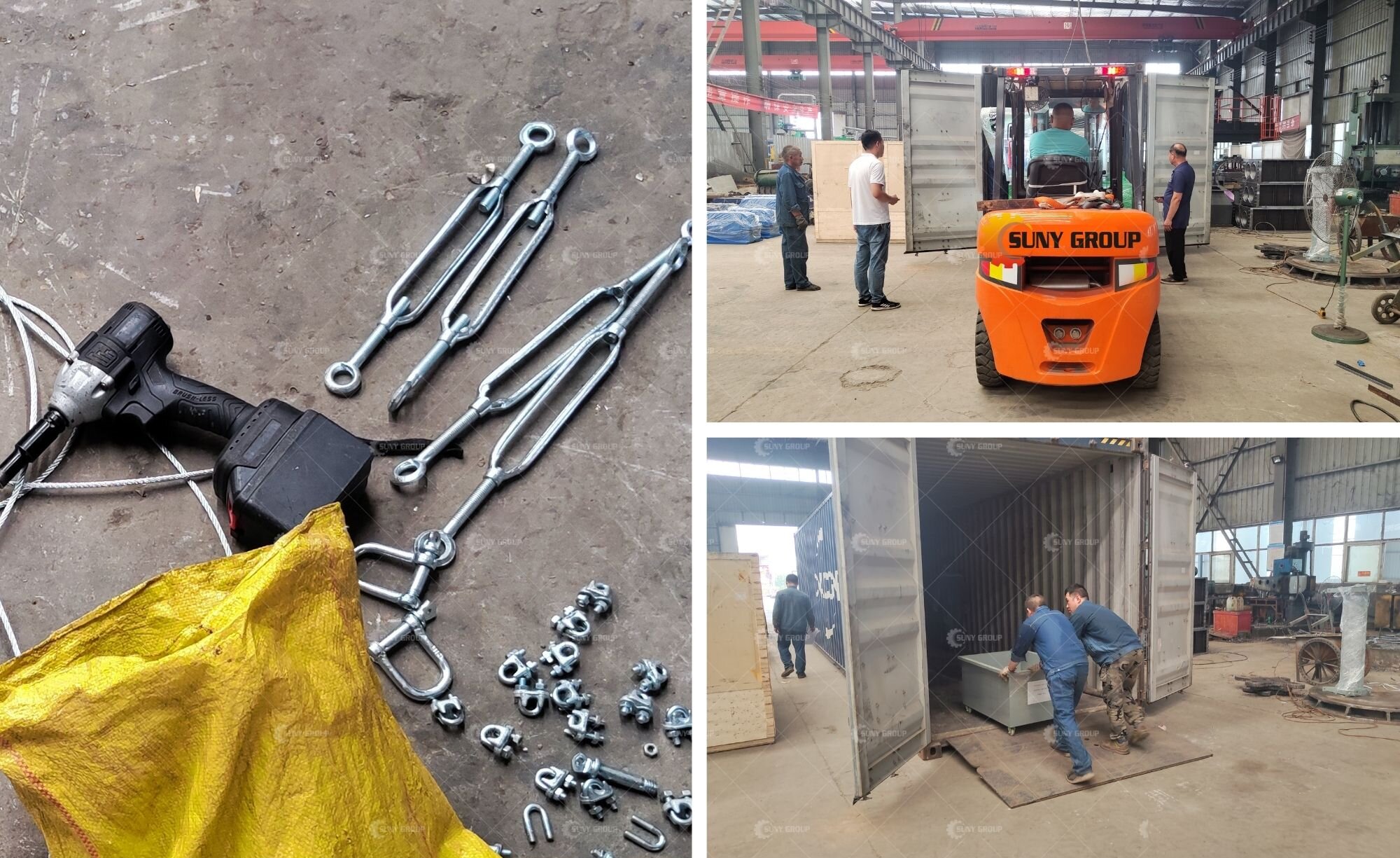

After receiving the customer’s order, SUNY Group quickly organized production. With years of technical experience and the efforts of a professional team, the production and testing process of the equipment was successfully completed. In order to ensure that the equipment will not be damaged during long-distance transportation, SUNY Group made particularly rigorous arrangements for the packing work. First, in the equipment packaging process, SUNY Group used high-quality protective materials and carefully wrapped each part of the equipment to prevent surface scratches or loose parts caused by transportation vibration. Secondly, when packing the equipment, SUNY Group used professional fixing technology to ensure that each device was firmly fixed inside the container to avoid possible position movement during transportation. In order to further ensure the safety of the equipment, the team also set up multi-point support in the container to prevent damage to the equipment due to tilting or center of gravity shift. After several hours of fine operation, all the equipment was finally loaded into the container, and after the final inspection and confirmation, it was ready to be shipped to Mexico.

300kg/h cable recycling machine

SUNY Group’s rich technical experience and service experience are not only reflected in the production of equipment, but also throughout every detail of equipment transportation and after-sales service. We believe that with the arrival of this batch of equipment, the cable recycling project of Mexican customers will be successfully launched and achieve significant economic benefits. At the same time, we strive to enable customers to start production immediately after receiving the equipment and smoothly carry out waste cable recycling projects. This will further deepen the cooperative relationship between SUNY Group and Mexican customers and lay a solid foundation for more cooperation opportunities in the future.