New Center

Cable Granulator, an efficient and environmentally friendly copper cable recycling tool!

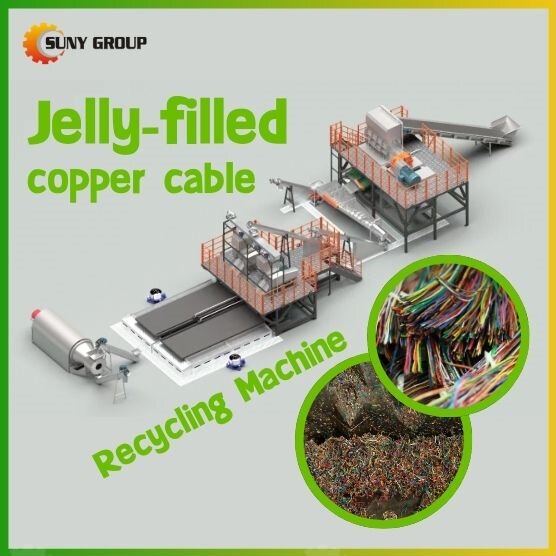

July 11, 2024In the process of modern industrialization, the recycling of waste cables not only helps to save resources, but also effectively reduces environmental pollution. In order to better serve customers, SUNY GROUP has recently launched a highly efficient and environmentally friendly copper cable recycling equipment – Cable Granulator. This equipment has quickly become a leader in the industry with its excellent performance and superior technology.

Cable Granulator is a mechanical device that can separate and recycle metals (mainly copper or aluminum) from plastics in waste cables. This equipment is widely used in the recycling of waste cables, especially in the wire and cable industry, the scrap metal recycling industry and related environmental protection industries. SUNY GROUP’s Cable Granulator adopts advanced design concepts and high-tech materials to ensure that the equipment is stable and efficient during operation. Its core components include:

High-efficiency crushing system: Using advanced crushing technology, the waste cables are quickly crushed to improve processing efficiency.

Fine separation system: Through multi-stage separation technology, copper and plastic are effectively separated, with a separation rate of up to 99%, ensuring the purity of the recycled materials.

Intelligent control system: The equipment is equipped with an intelligent control panel, which is easy to operate and monitors the operating status in real time to ensure safe and efficient operation of the equipment.

SUNY GROUP’s Cable Granulator has three major advantages: low-energy design, environmentally friendly materials and exhaust gas treatment system: the use of high-efficiency motors and optimized transmission systems significantly reduces energy consumption and saves production costs; the main body of the equipment is made of environmentally friendly materials to reduce the impact on the environment; it is equipped with advanced exhaust gas treatment devices to effectively purify the exhaust gas generated during the treatment process. In addition, the equipment has a high recovery rate, and the metal separation rate can usually reach 99% or even higher, maximizing the recovery of valuable metal resources.

In international trade, Cable Granulator equipment is mainly exported to countries and regions that need to deal with a large number of waste cables, including developed countries with strict environmental protection requirements and developing countries with gradually improving environmental awareness. By exporting Cable Granulator, suppliers can help customers recycle resources efficiently and promote the development of environmental protection. The main customer groups include scrap metal recycling companies, wire and cable manufacturers, and environmental companies focusing on resource recovery and environmental protection. These customers need efficient equipment to handle waste cables and production waste. Our team warmly welcomes customers from all over the world to contact us. We will provide you with customized solutions to meet your needs with a professional attitude and rich experience. We are online at any time to help you understand the machine.