New Center

Composition of copper wire recycling equipment

January 12, 2024Copper wire recycling equipment usually consists of multiple components and is designed to effectively separate the copper wires from used cables for recycling and recovery. The following are some of the main components that a 500kg/h copper wire recycling equipment may contain:

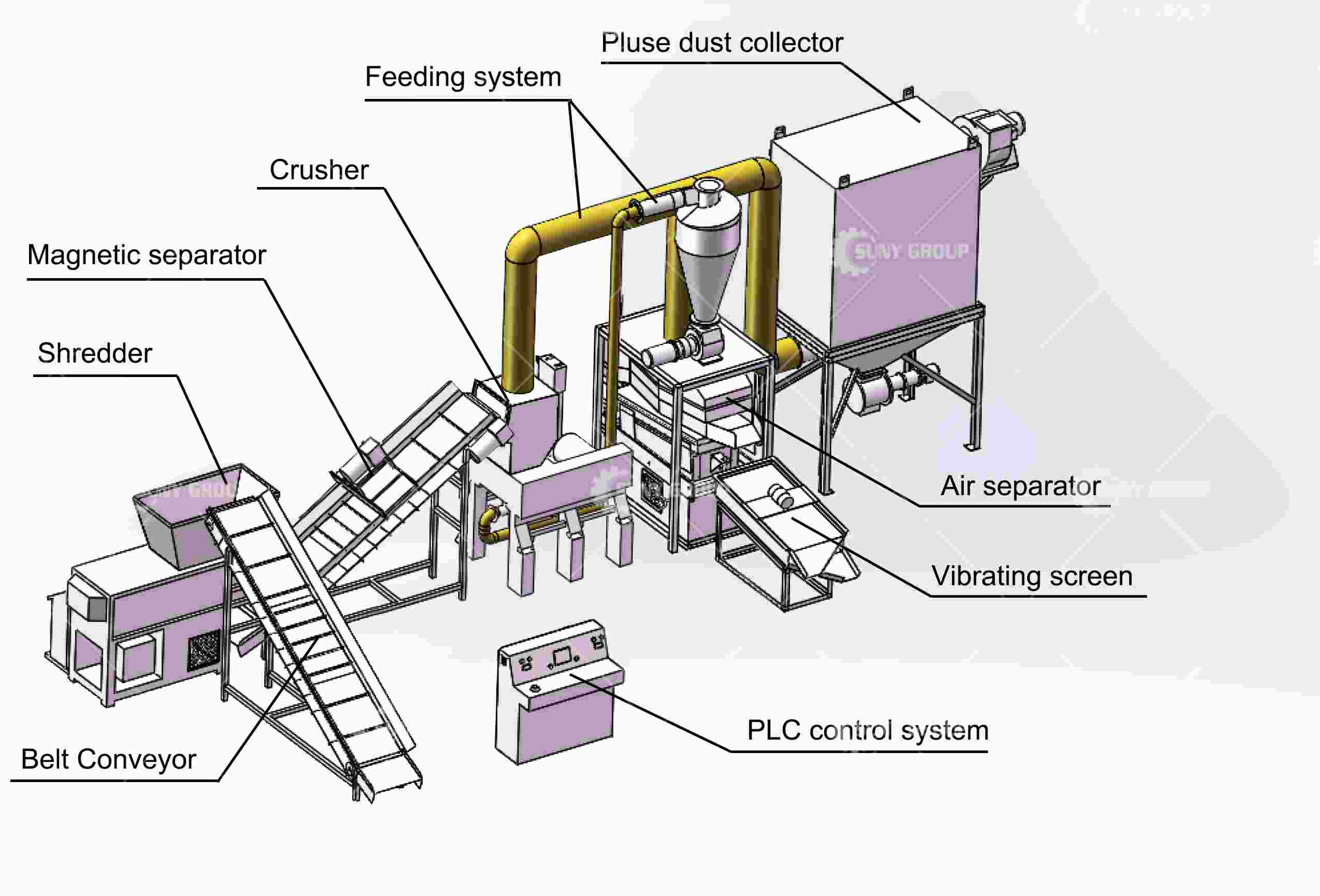

Conveyor belt system:

Driven by an electric motor reducer, it is used to transport waste cables from the inlet to the initial processing area of the recycling equipment. The fully automatic conveyor belt runs at high speed, smoothly and with low noise.

Preprocessing unit:

It includes equipment such as shredders and crushers, which are used to shred the outer insulation material of waste cables to expose the copper wires. This facilitates subsequent separation and disposal of waste cables. The adjustment of the discharge particle size is achieved by replacing screens of different specifications.

Magnetic separation system:

If other metals (such as iron) are present in the scrap cable, a magnetic separation system can be used to separate the iron material from the copper wire. High-voltage electrostatic separator is a kind of separation equipment that uses ultra-high voltage electric field to charge and separate materials. The main separation materials are conductors (metals) and non-conductors (plastics). Utilizing the different charging properties in the high-voltage electric field, the conductors are selected using electric attraction and inertial force. The electric adsorption characteristics of the non-conductors are used to adsorb the non-conductors on the Rotate the roller and use the brush to pick out the other side.

Vibrating screening system:

The vibrating screen is used to vibrate the stripped cable fragments and separate the copper wires from other materials (such as plastic, rubber). Vibrating screening can effectively classify materials according to their size and weight.

Air separation system:

Use airflow to separate the lightweight plastic or rubber pieces from the heavier copper wire. This can be achieved by adjusting the speed and direction of air flow. This airflow separator has adjustable wind direction and adjustable speed, stable adjustment means, and reliable operation.

Dust collection system:

Used to collect and treat dust and waste generated during the production process to ensure a clean environment and efficient operations. Its simple working principle is to use a ventilator to inhale or press dust-laden gas through a pipe into a box equipped with a filter bag. After the dust is removed by the filter bag, the clean gas is discharged from the box.

PLC control system:

Includes computer controls, sensors and automation equipment to monitor and adjust the entire recycling process. This helps improve efficiency and ensures stable operation of the equipment.

After the above introduction to the composition of copper wire recycling equipment and their respective characteristics, we can see what links a complete copper wire recycling machine should have. Suny Group has been focusing on waste recycling machines for more than 20 years. We have our own team of highly qualified engineers to customize the scrap copper wire recycling machine that best suits you. Please feel free to contact us at any time!