New Center

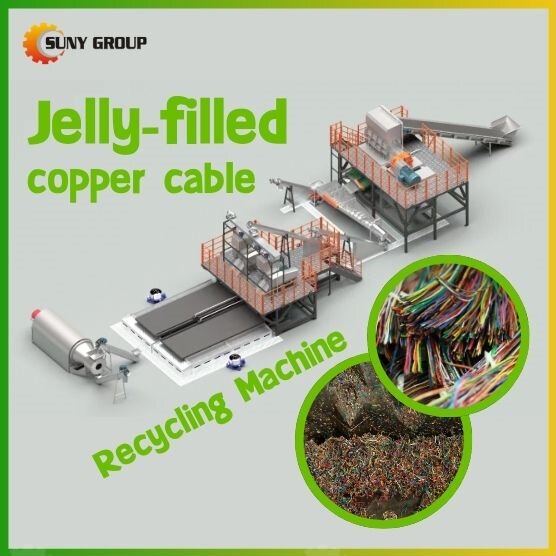

Excellent and efficient —- 300kg/h cable recycling machine field test.

April 23, 2024In this market of cable recycling machines where innovative technologies are constantly emerging, efficient recycling of waste cables is one of the advantages that customers value most. A week ago, a 300kg/h copper wire recycling machine from our factory was field tested at the customer’s site in Norway to check its performance and efficiency. Field test results show that this equipment has won unanimous praise from customers for its excellent processing capabilities and efficient recycling effects.

As an important scrap metal processing equipment, our company’s copper wire recycling machine has always attracted industry attention. As soon as the new technical solutions were launched and put on sale, they received favor from a large number of new and old customers, who expressed their intention to visit us. Next, let’s systematically introduce the new technical points:

cable recycling machines: The copper rice sorting machine achieves precise separation of copper and plastic. It does not require washing, is environmentally friendly and pollution-free, and achieves efficient use of resources.

Dust collection system: The equipment is equipped with a dust collection bucket and a filter filtration system to effectively collect and process the generated dust and fibers to ensure a clean and safe production environment.

Fully automated operation: Adopt an intelligent control system to realize fully automated operation of the equipment, improve production efficiency and stability, and reduce labor costs and operational risks.

Comprehensive utilization: The equipment can achieve 100% separation of copper and plastic without separate treatment, achieving comprehensive utilization of waste and making an important contribution to environmental protection.

1. PLC electrical cabinet: The advanced PLC electrical cabinet system is used to realize intelligent control and management of equipment and improve production efficiency and stability.

2. Crusher: The crusher adopts an optimized design. The torsion generated when crushing wires acts in the axial direction, reducing the stress on the bearings and extending the service life of the bearings.

3. Negative pressure pumping system: Equipped with a negative pressure pumping system, it can effectively reduce environmental pollution and improve the cleanliness and safety of the working environment.

4. Electrostatic dust removal and dust removal bags: Apply electrostatic dust removal technology and high-efficiency dust removal bags to achieve effective filtration and recycling of dust and fibers generated during the production process, and reduce environmental pollution.

5. Vibrating screen: Vibrating screen sorting technology is used to effectively separate copper and plastic and improve recycling efficiency and quality.

In order to strengthen cooperation and exchanges among the cable recycling machine industry, SUNY GROUP welcomes you to our factory to visit and discuss. Professionalism, efficiency, responsibility and integrity have always been the cornerstones of SUNY GROUP’s praise in the industry. Our services cover the world, if you are interested in our 300kg/h cable recycling machine or have any questions, please feel free to contact us.