New Center

How to choose the model of cable stripping machine? Detailed explanation of selection tips!

March 19, 2024With the continuous development of the wire and cable industry, the choice of wire stripping machine as an important equipment in wire processing has become increasingly important. When you’re looking to make more money for yourself or your business, the best thing you can do is fully understand which machines require the least investment and get the most bang for your buck. But with so many wire stripping machine models on the market, how do you choose? The right wire stripper for your needs becomes mission critical. Today, we propose a detailed analysis for you on how to choose a cable stripping machine model.

Understand the needs:

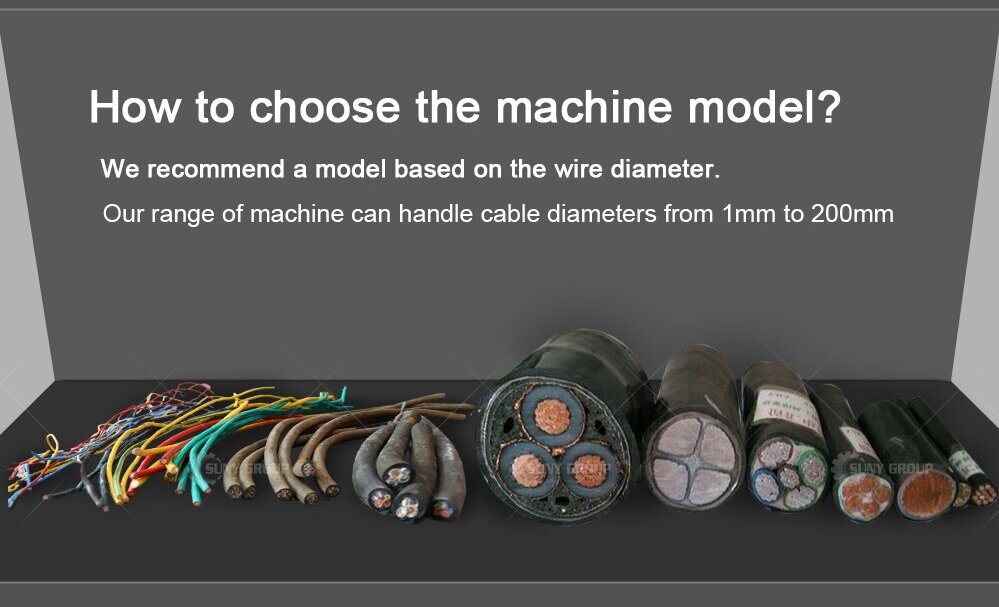

The first thing you’ll notice when you collect copper wire for recycling is that you end up with a variety of different sizes of wire. Therefore, before choosing a wire stripping machine model, you must fully understand your needs. Factors including the specifications of the wires you handle, the amount of processing per day, and the operating environment will all affect the choice. Different models of wire strippers are suitable for different gauges and materials of wire, so it’s important to make sure you choose the model that suits your needs.

Consider machine after-sales service

When choosing a wire stripping machine, you may wish to refer to other users’ reviews and feedback on after-sales service. By understanding the usage and after-sales experience of other users, you can have a more comprehensive understanding of the performance, quality and after-sales service of the wire stripping machine, which will help you make a more informed choice.

Learn about the excellent cable stripping machine features:

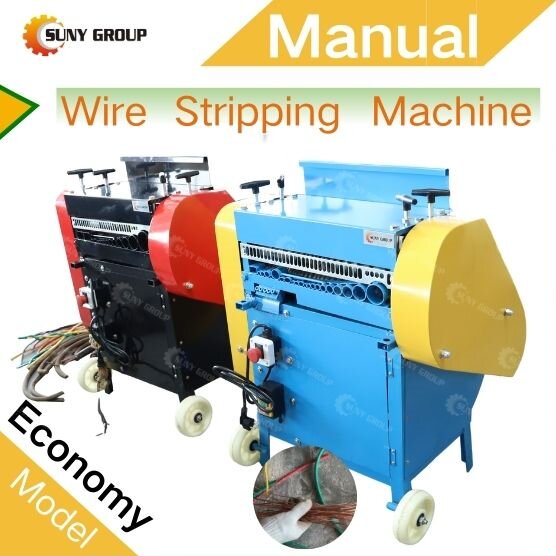

–Double stripping path with doubleknife, made the separation complete, Scroll design at the outlet avoide the wire damage.

— There are round holes and squareholes of different sizes, which canstrip wires with multiple centerdiameters

— Adjustable Wire Clamps: Prevent thin and soft wires from “escaping” the blade. Adjustable to clamp down the wire with

— Emergency Stop Switch: Easily accessible and quickly powers the machine off.

— Micro-Processor Control: Adapts to all kinds of wires automatically, delivering the best result.

— Quick Blade Change: Push out the shaft and the blade comes off

— The blade adjusting rod isconvenient to adjust the bladedistance according to the wirediameter

What are you waiting for? There is a lot of money to be made from recycling scrap copper wire, and Suny Group is the only wire stripping tool manufacturer that ensures you make more money. Don’t hesitate, contact us now to get the most professional cable stripping machine selection advice and start a new stage of your cable and wire processing journey!