New Center

How to use the cable stripping machine correctly?

October 15, 2024As the demand for waste cable recycling grows, there is an increasing need for the use of cable stripping machines in the recycling industry. When you purchase this machine, it is important to know how to use it correctly to achieve your recycling goals. Proper use of a cable stripping machine not only ensures safe operation but also significantly improves recycling efficiency and extends the life of the equipment.

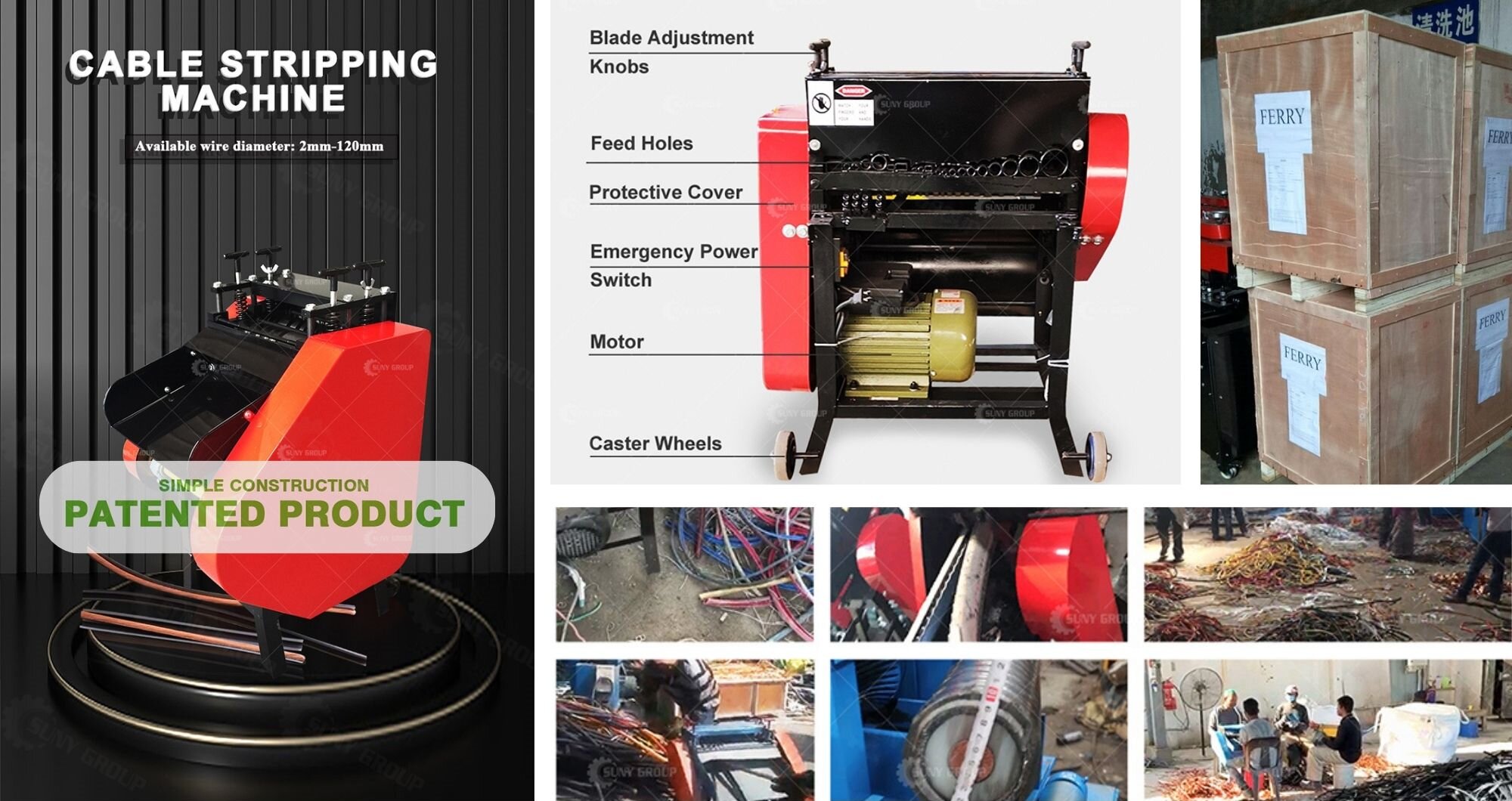

A cable stripping machine is a specialized device for stripping cable insulation from cables of various diameters, usually handling cables with diameters between 1mm and 200mm. It works by rotating the blades and applying pressure to strip the insulation from the outer layer of the cable, retaining the metal conductors inside. There are various types of cable stripping machines, each with different features, and common components include Blade Adjustment Knobs, Feed Holes, Protective Cover, Emergency Power Switch, Motor, and Caster Wheels. Together, these components form the core function of a cable These components together form the core functionality of the cable stripping machine, enabling it to perform the task of stripping wires efficiently and accurately.

Before beginning operation, it is important to perform safety checks and preparations. First, check that all parts of the cable stripping machine are intact, especially the condition of the blades and power connections. Also, make sure the machine is off before handling cables or adjusting settings. In addition, wearing proper protective gear should not be overlooked, including gloves and goggles, while avoiding loose clothing to prevent accidents.

Choosing the right knives and molds is key to ensuring quality wire stripping. Adjust the depth and pressure of the blade according to the size specifications of the cable to avoid cutting the wire. After ensuring that the cable is properly aligned, you can start the machine and let the cable pass smoothly through the cutting blades. During the stripping process, monitor the progress of the operation, especially for longer cables, and guide it manually if necessary to ensure that the stripping process runs smoothly. For motorized cable stripping machines, the cable is usually pushed automatically by simply holding it manually.

Once the outer jacket of the cable has been stripped away, exposing the copper core, you have completed a scrap cable stripping for recycling. The whole process can be continued until all prepared cables have been stripped for recycling. At the end of the job, be sure to turn off the cable stripping machine and clean up the work area to keep the equipment and the environment tidy.

Routine maintenance and upkeep are important measures to ensure the stable operation of the cable stripping machine for a long time. Regularly check the sharpness of the blades to ensure smooth operation. Avoid overloading the machine and strictly observe the cable size range specified by the equipment to prevent damage caused by overloading. In addition, the stripped-down insulation should be treated in an environmentally friendly manner to ensure that it does not pollute the environment.

The benefits of using a cable stripping machine correctly are obvious. It not only improves work efficiency and saves time and labor costs, but also ensures the quality of stripped wire and reduces the scrap rate. At the same time, it enhances the safety of operations, reduces the risk of accidents, and ensures the health and safety of staff. To summarize, mastering the correct use of a cable stripping machine is the basis for achieving efficient recycling. If you need to know more details about the operation of the machine, please feel free to contact us, we have professional technicians and overseas after-sales installers standing by.