New Center

Recycle Jelly Filled Cables: Solutions, Advantages and Process.

July 13, 2024The recycling of jelly-filled cables, commonly used in telecommunications, presents unique challenges and opportunities. Jelly filled cable is an underground cable having polythene as insulation on conductors and the inter-spaces between the conductors is fully filled with petroleum jelly. Petroleum jelly prevents ingress of moisture and water inside the core in the event of any damages to the cable.These cables, filled with a gel-like substance to prevent moisture ingress, require specialized processes for effective recycling.

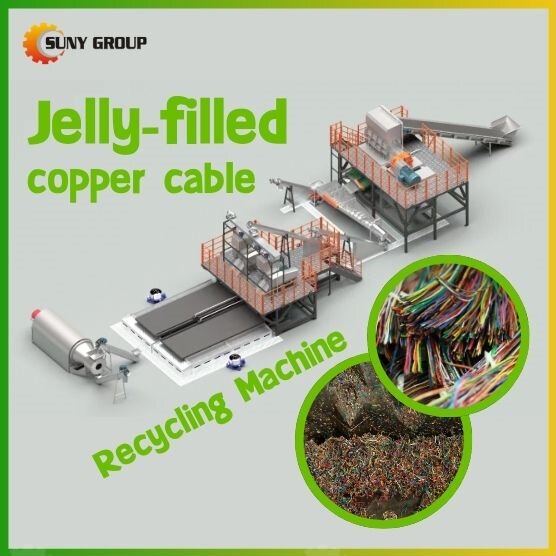

There are three overall solutions, namely mechanical recycling, carbonization (thermal) recycling, and chemical recycling. Let’s first discuss the mechanical recycling of Jelly filled cables. Mechanical recycling involves physically separating the different components of the cable, including gel fillers, metal conductors, and plastic insulation. Through the initial collection → crushing → cleaning → separation, the final material that can be recycled is obtained. The advantage is that it is more environmentally friendly, avoids the use of harmful chemicals or high energy input, and has a high metal and plastic recovery rate. The process can recycle a large amount of cable materials, especially metals such as copper and aluminum, which are valuable in the secondary market.

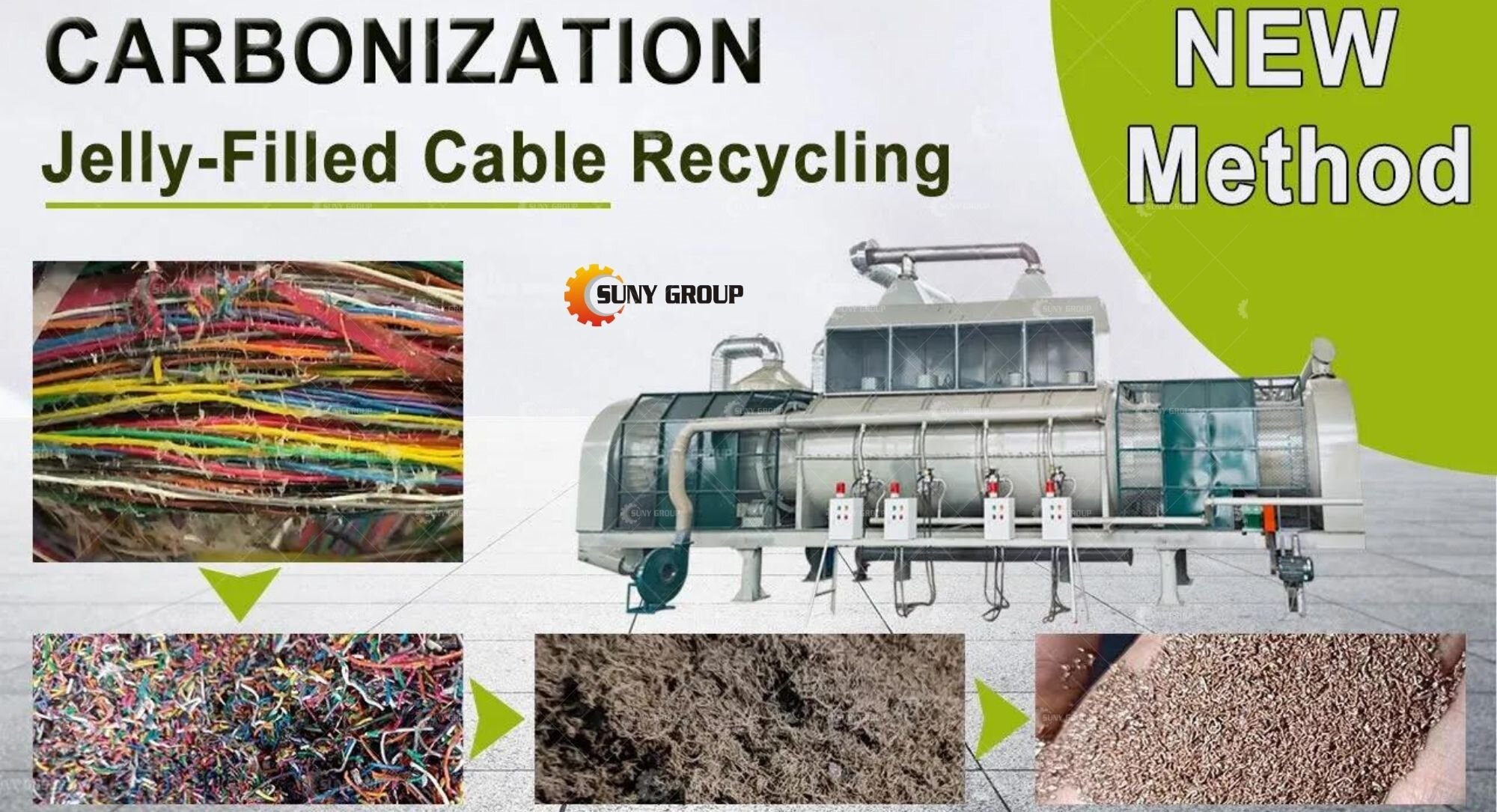

Then there is the carbonization (thermal) recycling of Jelly filled cables. Thermal recycling uses heat to decompose jelly fillers and other ingredients. The metal is recovered after the jelly and plastic are burned. First, the oily filled cable is chopped into small pieces, and then the cable fragments are placed in a carbonization furnace. This process removes grease and carbonizes the plastic layer. After carbonization, we can further separate copper and carbon residue. This method can efficiently process a large number of cables, especially effectively decomposing gel fillers. After the gel and plastic materials are incinerated, the metal is easily recycled. More economical and environmentally friendly.

Finally, there is the chemical recycling of Jelly filled cables. Chemical recycling involves using solvents to dissolve the jelly filler and separate the cable components. Chemical recycling can achieve high purity of recycled materials and is very suitable for cables with complex structures. The process can effectively dissolve the gel filler, making material separation simple. However, chemicals need to be handled with care. If chemicals are not handled properly, they may cause harm to the environment. The policies of most environmentally friendly countries do not support this option.

In general, in the global recycling market, mechanical recycling and carbonization (thermal) recycling are the main solutions for processing Jelly filled cables. If you are interested in our technology on jelly-filled cables recycling, please never hesitate to contact us for detailed discussion.