New Center

Streamlined Copper Wire Recovery with Innovative Cable Recycling Machinery

September 4, 2024With the increasing depletion of resources and growing environmental awareness, recycling copper has become an important means of sustainable development. The growing global demand for copper has fuelled the growth of the recycling industry. Recycling copper is more cost-effective than mining new copper. The recycling process not only saves resources but also reduces environmental pollution, offering significant economic and environmental advantages. As a key conductive material, copper is widely used in industries such as electrical, construction, and transport. Its diverse applications further stimulate market demand, and these factors make copper wire recycling a profitable and sustainable business option that continues to attract a variety of entrepreneurs and recyclers.

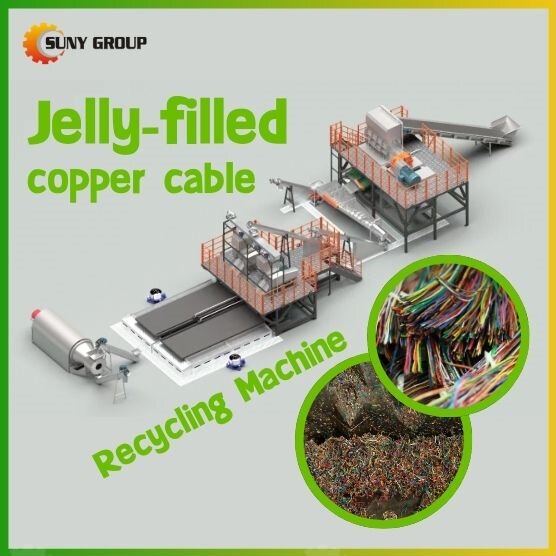

Specialized machinery and equipment play a vital role in the copper wire recycling process. These machines not only increase the efficiency of recycling but also ensure that the entire process is environmentally friendly and economical. The core equipment of a copper wire recycling machine consists of a crusher, a sorting system, and a dust collection system, which work in tandem so that scrap cables can be efficiently converted into reusable, high-quality copper material.

The crusher is the first step in the cable recycling process, and it is responsible for cutting various types of scrap cables into small segments. Modern crushers are well-designed with powerful cutting capabilities and can handle all types of cables, including those with hard outer jackets or thicker diameters. By cutting efficiently and consistently, the crusher creates ideal conditions for subsequent sorting processes. Our crushers are also equipped with extremely wear-resistant knives, which extends the service life of the equipment and reduces maintenance costs.

The crusher is the first step in the cable recycling process, and it is responsible for cutting various types of scrap cables into small segments. Modern crushers are well-designed with powerful cutting capabilities and can handle all types of cables, including those with hard outer jackets or thicker diameters. By cutting efficiently and consistently, the crusher creates ideal conditions for subsequent sorting processes. Our crushers are also equipped with extremely wear-resistant knives, which extends the service life of the equipment and reduces maintenance costs.

The sorting system is at the heart of the entire recycling process. The sorting system efficiently separates copper from plastic using advanced vibrating screen technology and electrostatic sorting. The vibrating screen sorts the mixed material into different particle sizes, while the electrostatic separation utilizes the difference in charge between the materials to accurately separate the copper from the plastic. This process not only ensures high-purity copper recovery but also efficiently recovers plastic materials, further improving resource efficiency. Our sorting systems are compact and easy to operate and can be adapted to the needs of recycling operations of different sizes.

Dust collection systems play an important role in environmental protection. As dust is inevitably generated during the crushing and sorting process, dust collection systems can effectively capture and dispose of this dust to reduce environmental pollution. Our dust collection systems are not only powerful in removing dust but also in compacting it and reducing waste emissions. Through the operation of the dust collection system, we ensure that the recycling process is green and complies with various environmental regulations.

With the advancement of technology, the level of automation and intelligence of copper wire recycling machines is constantly increasing. Equipped with advanced PLC control systems, modern recycling machines are capable of fully automated operation, which greatly reduces the complexity and error rate of manual operation. At the same time, the energy consumption of these machines is significantly reduced, further improving the economics of the recycling process. Through precise control and optimized operating processes, copper wire recycling machines can maximize recycling efficiency, ensuring that the copper in every cable is efficiently recovered.

The copper wire recycling business is receiving a lot of attention due to its huge market potential. Copper recycling not only meets the growing market demand but also makes a significant contribution to environmental protection. The following are some of the main reasons for choosing to engage in the copper wire recycling business: copper recycling is in high demand, the business has the potential to be profitable, it is environmentally friendly, the barriers to entry for the industry are relatively low, the increasing amount of e-waste provides abundant resources for recycling, the diversified applications of copper ensure the market demand, the governments of many countries and regions provide incentives to support the recycling industry, the operation of copper wire recycling is relatively simple, recycling is becoming a global trend, and this is the most important factor for the industry. Recycling is becoming a global trend and the business is highly scalable.

Our team will provide you with the best quality copper wire recycling products and services with integrity, professionalism, and responsibility. We not only provide efficient and reliable recycling equipment but also offer comprehensive technical support and after-sales service to ensure that your recycling business can run smoothly and successfully. If you are interested in our copper cable wire recycling machine or have any questions, please contact our team today. We will be happy to provide you with the best quality solutions to help you succeed in the copper wire recycling field.