New Center

Wire waste recycling machine: solving the “disposal problem” of waste wires

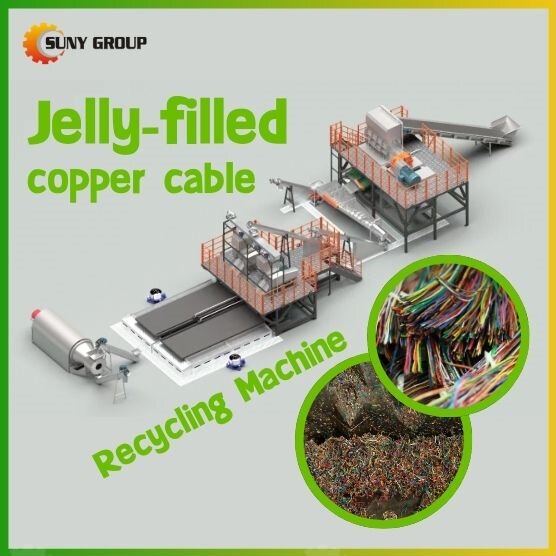

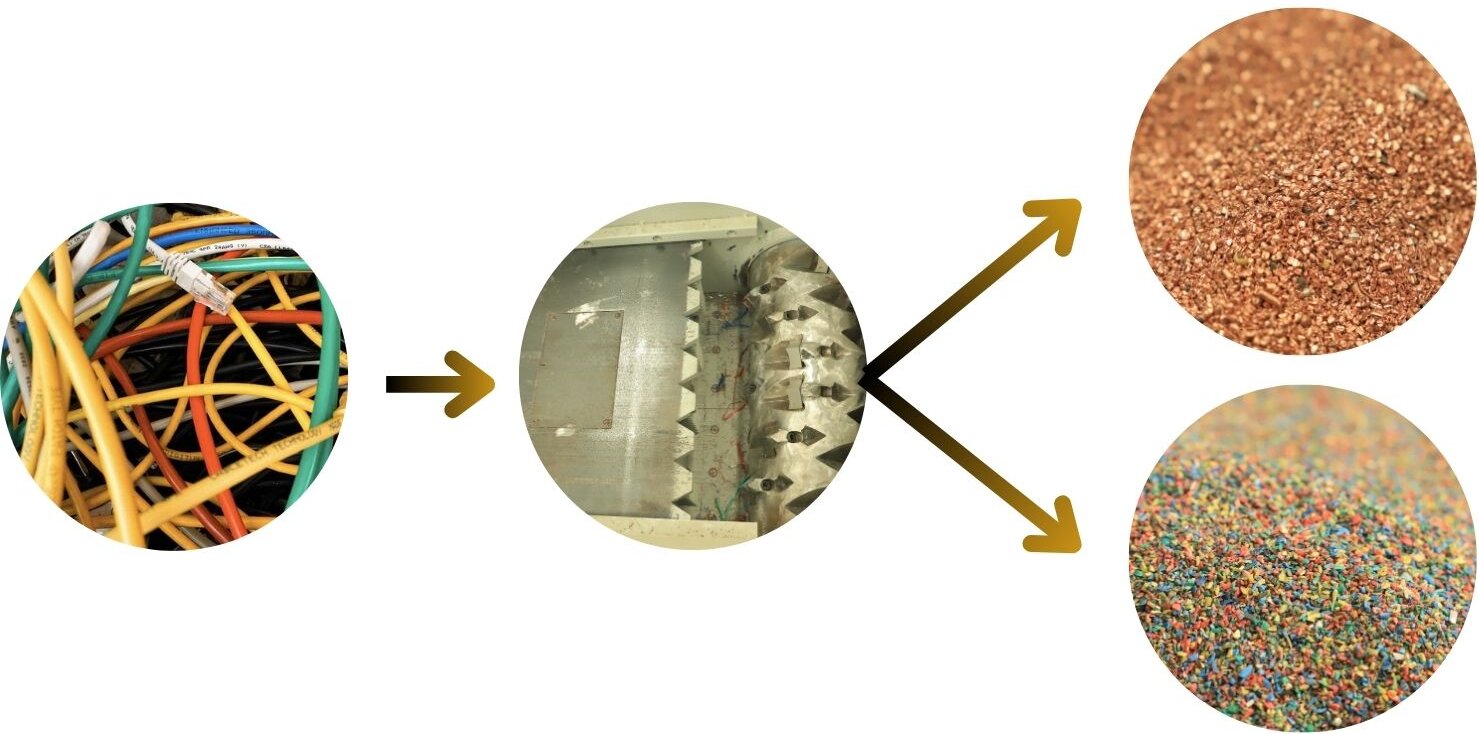

March 20, 2024Copper cable wire recycling machine is an environmentally friendly machine, also known as copper wire granulator or wire scrap recycling machine. Copper wire granulator is used to recycle waste cables and wires. It usually consists of a feed conveyor, a copper wire shredder, a conveyor belt and a separation system. The feed conveyor is used to feed copper wires and cables into the machine, while the copper shredder shreds the wires and cables into small pieces. A conveyor belt then moves the shredded material to a separation system that separates the copper from the plastic insulator without using fire, water or chemicals and causing no secondary pollution to the environment.

Our copper wire recycling and separation rate high machine can reach 99.9%, you can see there is no copper in the plastic, and there is no plastic in the copper. This produces clean copper pellets that can be sold to various industries for use in new products. Any building wires and cables, industrial cables, low-voltage cables, flexible wires, fixed wires or special purpose wires and cables, such as battery leads, ship wires, busbar entry cables, electric vehicle cables, tow cables, distributed generation cables, diameters greater than 100 mm Armored cables, technical cables of any size, submarine cables in the presence of fats and oils, very fine wires (telephone lines, data cables, computer recovery cables), cables for electrical and electronic equipment, capillary cables, contaminated with sticky or oily materials All cables, etc. generated after the vehicle is dismantled can be recycled through the copper wire recycling machine.

Copper wire recycling machines recycle scrap cable wires through a crushing and separation process, so there are no restrictions on input cable wire size or type. We have extensive experience in cable recycling and have a range of specialist equipment capable of handling from 50 to over 1000kg/hour. Scrap cable recycling machines are available in different sizes and configurations, depending on the specific requirements of the application. They can be manual or fully automatic. In addition to the standard configuration, we can also configure other equipment according to customer needs, such as: waste cable shredder (used as primary crushing), iron remover, electrostatic separator, etc. Through installations around the world, they have proven to be the most effective size reduction and separation solution for large quantities of scrap cables and electronic waste.

As a professional recycling equipment manufacturer, we have extensive experience in the field of waste wire recycling, and we have reasonable copper wire pelletizing machine prices. If you are looking for a reliable copper wire granulator manufacturer for sale, or you have any questions about waste cable recycling, please feel free to contact us and we will contact you within 24 hours. We will wholeheartedly provide you with customized solutions, professional technical support, regular equipment maintenance, comprehensive waste recycling solutions, and continuously innovative products and technologies.