Cable Recycling Machine

- Home

- Cable Recycling Machine

- 1000kg/h Copper Wire Recycling Machine

| Parameter | Value |

|---|---|

| Feed Diameter | 5-20mm |

| Voltage | 220v |

| Power | 95kw |

| Weight | 8200kg |

| Size | 12×4.1×4.5 |

| Capacity | 1000kg |

1000kg/h Copper Wire Recycling MachineProduct Code : ZY-CW1000

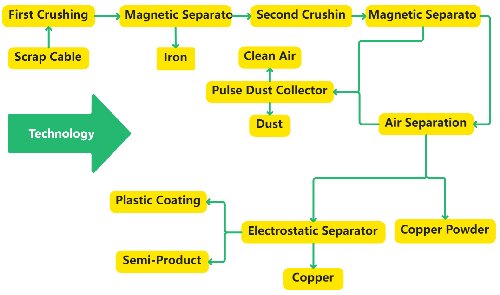

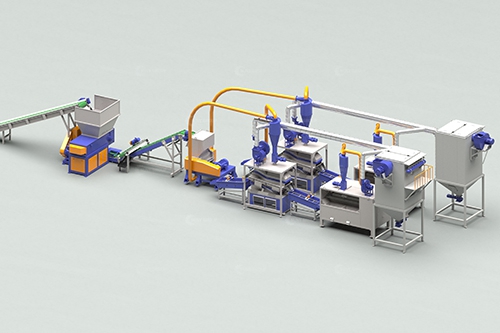

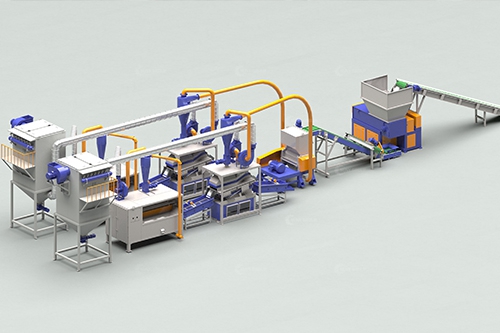

Our 1000kg/h copper wire recycling machine is an advanced cable granulator designed for efficient processing of waste copper cables. The equipment is equipped with a high-power shredder and crusher, which can quickly and finely shred the waste cables and reduce the preparation time before processing. The double vibrating screen and double dust removal system are used to effectively separate and collect copper and plastic, ensuring a recycling rate of up to 99.8%.

At the same time, the equipment has a dual aggregate function, which can simultaneously process waste cables of various specifications and types, improving production efficiency and flexibility. The PLC control system makes the operation simple, and only a small number of operators are required to achieve efficient production. Especially for small copper wires, it can also be effectively processed.

Contact WhatsApp Online

Try it now and upgrade your wire stripping experience!

Product Highlights:

- 1. Mainly used to handle wires, miscellaneous wires, communication lines, data lines, headphone lines, etc. High efficiency and energy saving, favorable price, stable performance and global after-sales service.

- 2. Integrated structure design, compact structure, small occupied area, easy to move and it can be operated by putting it on flat ground and turning on the power supply.

- 3. It adopts PLC control, the appearance is simple and beautiful and the operation is simple. One operator can operate it.

- 4. Gravity separation adopts Italy air suspension separation process, and the vibration frequency and material suspension air supply device can be adjusted precisely according to different materials.

- 5. Crushing system adopts SKD-11 alloy cutting tool, the processing hardness is HR58. It can ensure the high-wearing resistance as well as a certain tenacity of the crushing blade.

- 6. The operation of the complete set of equipment is fully enclosed, it is equipped with an advanced pulse dust removal system that effectively collects dust in the production process and discharges it from the dust outlet.

- 7. Our company is equipped with electrostatic selection equipment, the remaining copper in the plastic can be sorted out again, so that there is no plastic in the copper and no copper in the plastic.

After-sales Service:

- Have an experienced overseas installation and commissioning technical team.

- Detailed operation manual and powerful online technical support.

- Provide buyers of finished product materials so that you don’t have to worry about how to sell finished products.

- We can guarantee lifetime supply of equipment accessories.

Machine Details:

- ① The device operation buttons are simple and clear, providing users with an intuitive, fast and operation experience that does not require tedious learning.

- ② Transparent observation window, convenient for viewing discharge status, humanized design.

- ③ The internal design is compact to reduce the volume of the equipment, and the exterior is fully enclosed to minimize noise and improve equipment safety.

- ④ The equipment adopts a fully enclosed design, button operation, and high safety. There are observation windows and discharge openings at the front and rear

- ⑤ Environmental protection equipment, recycling rate 99%

- ⑥ In stock, orders will be shipped on the same day. The device is packed in wooden boxes with metal corners for external reinforcement and international standard internal fixing.

- ⑦ The equipment complies with environmental protection regulations and standards. No pollution will be produced during the production process. Equipment equipped with dust removal structure

Machine Model

Our Customer cases

Company News

Why Choose Us?

-

Cutting-Edge Technology:

Suny Group leverages state-of-the-art technology, ensuring you benefit from the latest advancements in the industry.

-

Proven Track Record:

With a solid history, we have consistently delivered reliable and high-performance solutions, earning the trust of our clients.

-

Global Standards Compliance:

Our commitment to quality is reflected in our compliance with international standards, providing you with products that meet the highest benchmarks.

-

Reliable Customer Support:

Suny Group is not just a supplier; we are your reliable partner. Benefit from our responsive technical support, comprehensive training services, and dependable maintenance.

Inquiry Form